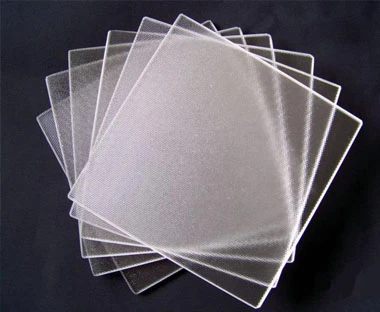

The raw materials such as low-iron ultra-clear silica sand are melted in a glass kiln, and then are pressed and formed by a calendering machine, annealed and cooled, and finally cut to obtain ultra-white patterned glass. The special design patterns on the glass surface significantly improve the transmittance of the glass.

Using internationally leading technology and equipment, an antireflection coating is applied to the surface of high-transparency ultra-clear patterned glass, and then the product is tempered to effectively reduce the sunlight reflection ratio on the glass surface, thus improving the conversion efficiency of the modules.